Concurrent Session

Session: Spillway Gates

CS23B - Concurrent Session 23B: Tainter Gate Trunnion Pinching Moments and How They Affect Trunnion Friction

Tuesday, September 24, 2024

2:00 PM - 2:30 PM MT

Location: Colorado Convention Center, Meeting Room 505-507

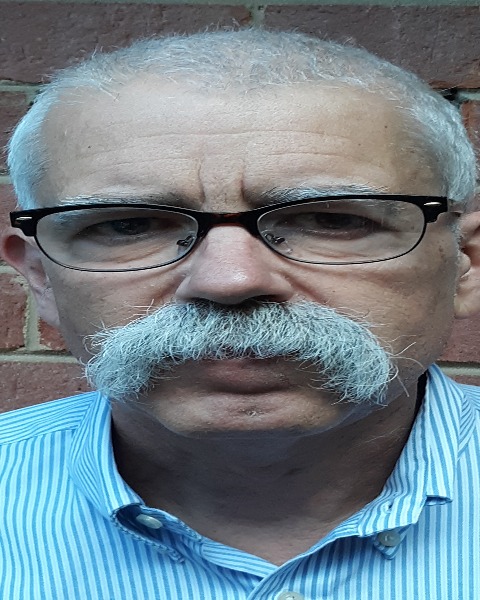

Bruce Brand

Hetrodyne Engineering

Presenter(s)

Tainter gate operating load cases incorporating trunnion friction are standard practice for gate evaluations and often a critical load case to consider for the performance of gate strut arms and end frame members and connections. For cylindrical pins with sleeve/journal type bushings (i.e., not spherical bearings), the trunnion friction calculated at the pin-to-bushing interface must consider not only the upstream/downstream and vertical trunnion force reactions, but also the moments about these axes. Cylindrical pin design without spherical bearings, which is a very common design for Tainter gates, only permits rotation about the cross-stream axis parallel to the pin; therefore, the moments about the two axes orthogonal to the pin centerline should be fixed for Tainter gate analyses with this pin/bushing arrangement. These calculated moment reactions will induce pinching/clamping effects on the trunnion pin and may add to the total trunnion friction that should be considered at the pin-to-bushing interface. How much this effect influences the total frictional moment is dependent on the relative magnitudes between the trunnion force and moment reactions and the length of the pin/bushing contact.

Documentation on how to incorporate this pinching/clamping effect on trunnion friction calculations is not provided in current industry guidance. This paper derives equations and provides supporting figures to allow incorporation of these effects in a logical manner. Furthermore, gate designs that may be more prone to significant pinching/clamping that increases overall trunnion friction will be explored and discussed and a couple of case studies will be described.

Documentation on how to incorporate this pinching/clamping effect on trunnion friction calculations is not provided in current industry guidance. This paper derives equations and provides supporting figures to allow incorporation of these effects in a logical manner. Furthermore, gate designs that may be more prone to significant pinching/clamping that increases overall trunnion friction will be explored and discussed and a couple of case studies will be described.